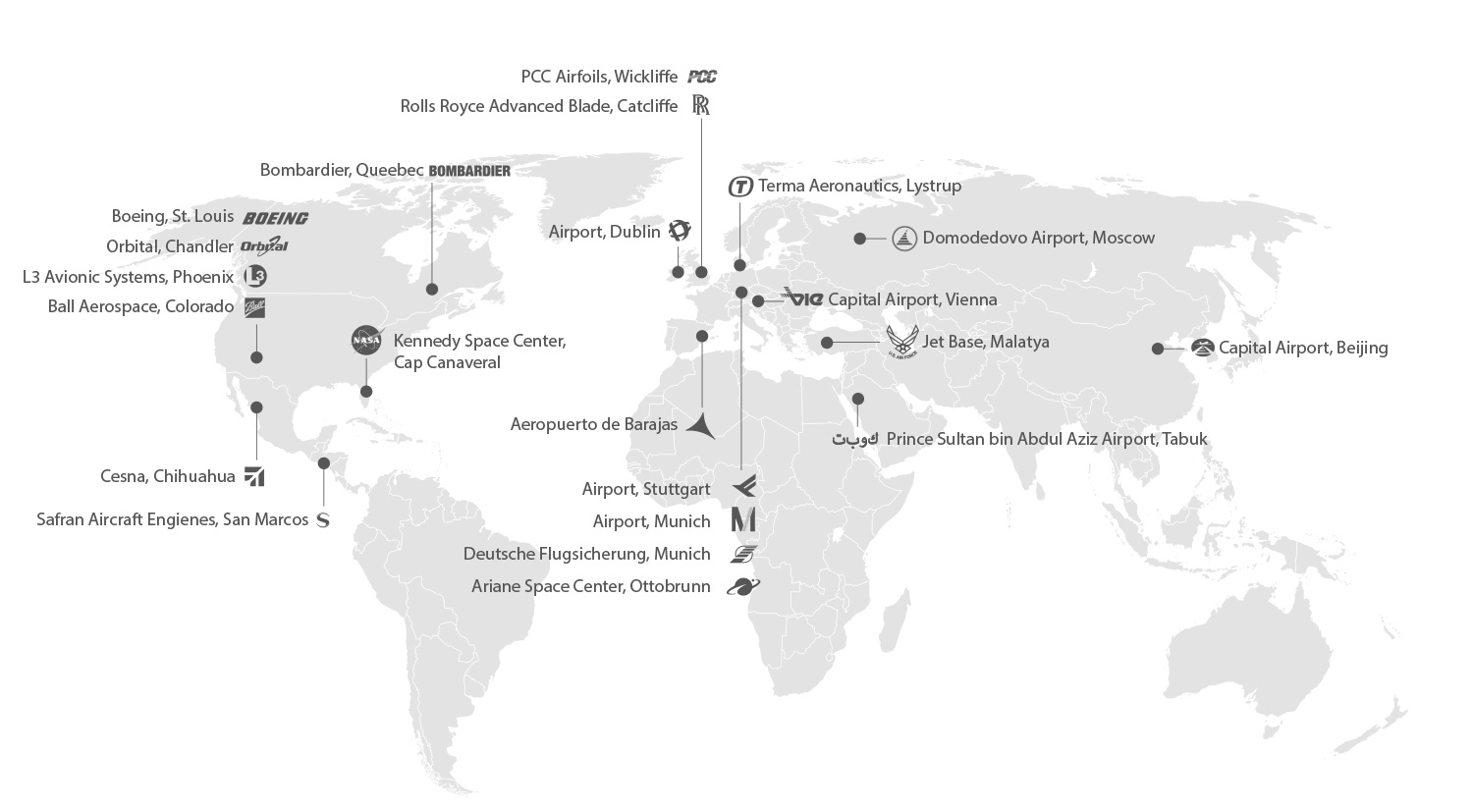

Dehumidification for the aerospace industry

For the aerospace industry, reliable functional quality of all components is essential. Insufficient and excessive humidity can cause damage and defects to electronic components with potentially disastrous consequences. It affects the quality of polymerization of composites, sealants, coatings and welds, so that parts can deform, become porous or the quality of the surface is impaired.

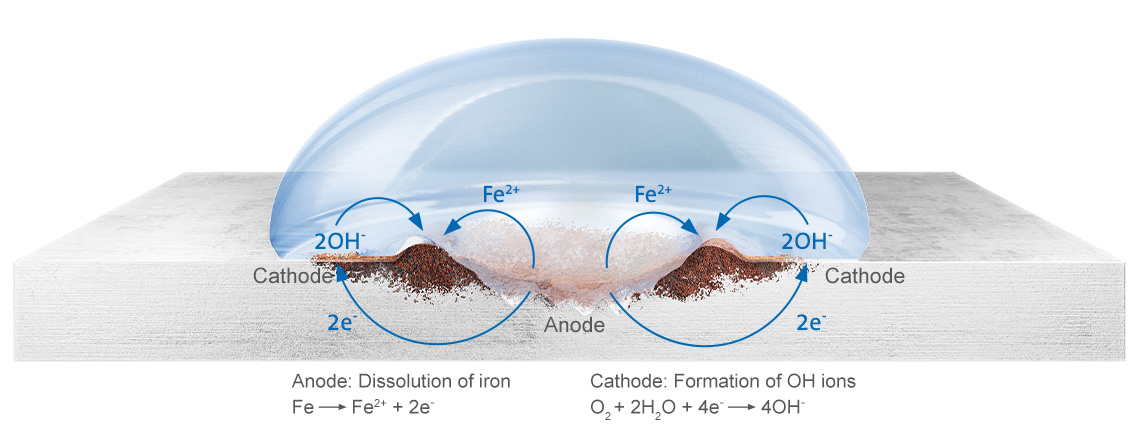

Corrosion of steel on a drop of water

Iron cannot rust in the mere dry air. However, when moisture settles on the metal, oxygen (O2) and water (H2O) begin to react to form hydroxide ions (OH-). To balance the electrons required for this reaction, the iron oxidizes, i.e. it releases its electrons, which are then absorbed by the oxygen. This process produces iron oxide. Where the electrons have been withdrawn, an electron shortage occurs and positively charged iron atoms (Fe2+) are released. These migrate into the water droplets and combine there with the negatively charged hydroxide ions (OH-). In the first step, iron(II) hydroxide is formed as a result of different charges. Further reactions with water, oxygen and hydroxide ions result in ever more continuous reactions from which iron(III) oxide and iron(III) hydroxide are formed. They settle on the metal surface and give the rust its typical appearance. Unlike with metals such as aluminum, the process is only stopped when iron is no longer present.

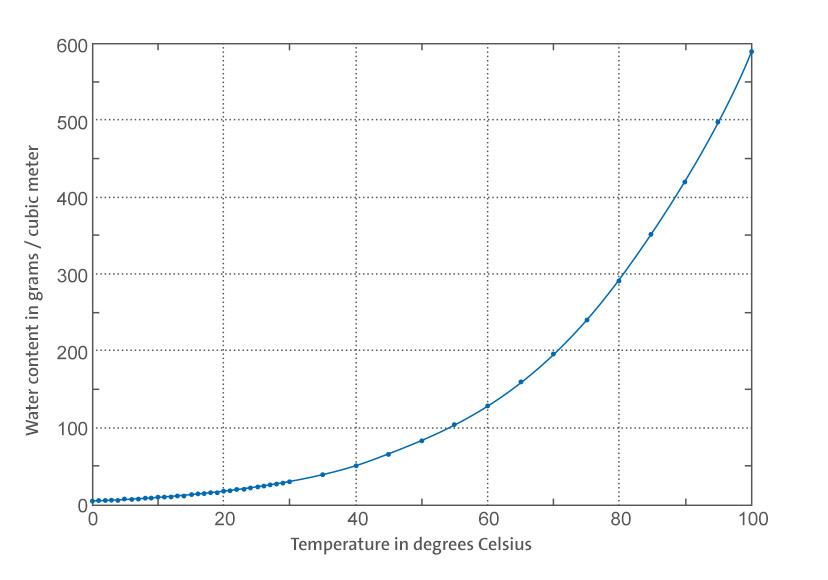

Saturation of water vapor in the air

Condair quality

Our customized systems offer professional solutions for air humidification and dehumidification for the size and conditions of each individual room. Because professional planning is the basis for functional quality and energy efficiency, we are happy to assist you right from the planning phase.

Hammam, Caldarium and Rhassoul

A hamam is a steam bath in which a special bathing ceremony is held,

and is an important part of Islamic bathing and physical culture.

The focus is...

Steam bath and steam shower

Nowadays, many hotels and health clubs offer spa facilities for the well-being of their guests and members:

A swimming pool, a sauna and more and mor...

Office Rooms

Employees must feel comfortable as they work. Motivation, efficiency, and health can be improved through contemporary design of the workplace. The ri...

Fashion Industry

An “electric shock” when touching a clothes rail; hair that takes on a life of its own when trying on clothes. Dry air can really spoil the fun of go...

Food Storage

Hygroscopic (moisture-drawing) foods interact with ambient humidity. They either absorb water vapor from their environment or give off water vapor.

T...

Data Center

In data centers, humidifiers primarily ensure that electrostatic discharges and damage to sensitive hardware are prevented.

Electronic Industry

The dryer the air, the quicker electrostatic charges occur and the stronger they are. Consistent protection against ESD (electrostatic discharge) has...

Automotive Industry

To achieve optimum results, paintwork must be applied to vehicles in optimum environmental conditions. Crucially, humidity and temperature must meet ...

Call Centers

A good room air humidity in a call center not only ensures the employees’ well-being, but also their performance and health. Today, respiratory illne...

Museums

Museums are charged with the task of preserving treasures of humanity and art. The innumerable, often unique and irreplaceable exhibits are worth man...